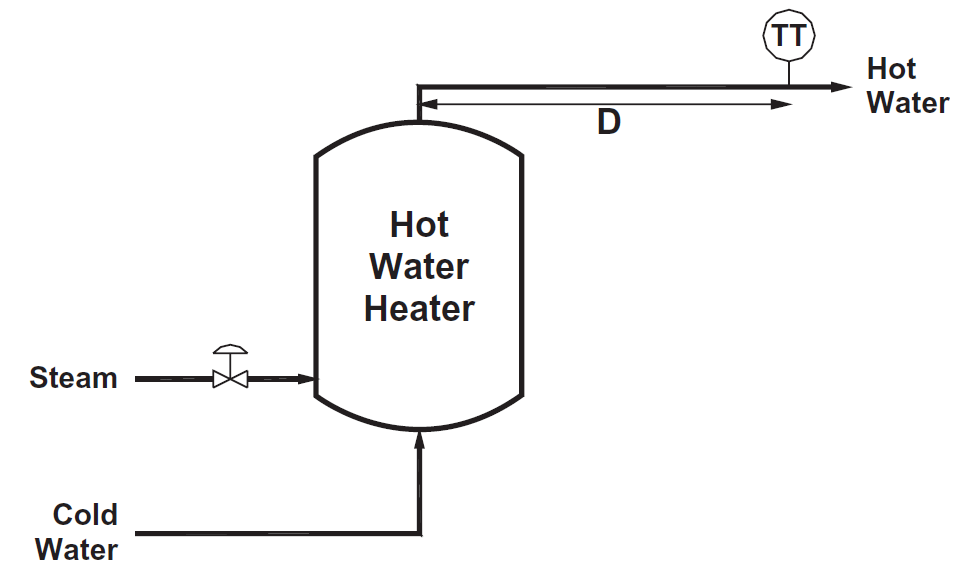

Figure 3.9. Temperature measurement device located downstream.

Control difficulty is increased by dead time

The dead time can be computed as the length divided by the speed.

…in Figure 3.9. As the mixing of steam and cold water to produce hot water occurs in the tank, the temperature of the water in the tank is the true indicator of the state of the process. When the hot water temperature transmitter is located downstream, the temperature controller does not know the current value of the temperature of the water in the tank. Instead, the controller only knows what the temperature was at some time in the past. In essence, the controller is taking actions based on old information, which is never a good idea.

You do not know where you are; you only know where you have been. Your driving performance is seriously impaired. Furthermore, if you insist on driving this way, take some advice: slow down!

Actually, we have to give this same advice to the temperature controller for the hot water process. We do this by reducing the controller gain.

When the dead time is large, the gain must be reduced substantially, resulting in a very slow loop. The usual complaint in large dead time processes is that the controller is so slow that it is useless.

As the dead time increases, more overshoot is generally observed, and… oscillations will become pronounced.

The larger the dead time,… the slower the response.[1]

Control difficulty is reduced by capacity

Capacity is where a process stores variable amounts of mass or energy.[2]

The time constant… is always the ratio of holdup to throughput. For material balances, the holdup is material and the throughput is material flow. For energy balances, the holdup is energy and the throughput is energy flow.

Control difficulty can be quantified

…controls… can cope with time constants… far better than with dead time.[1]

The parameter

![]()

…has the property 0 ≤ control difficulty ≤ 1…

…processes with small control difficulty are easy to control, and the difficulty in controlling the system increases as control difficulty increases. Systems with control difficulty = 1 correspond to processes with pure time delay, which are difficult to control well.[3]

…dead time is the “difficult element to control.”[1]

- Smith, Cecil L. Practical process control: tuning and troubleshooting. John Wiley & Sons, 2009, pp. 72, 83, 85, 87-90.

- Shinskey, F. Greg. Process control systems: application, design and tuning. 4th ed., McGraw-Hill, Inc., 1996, p. 22.

- Åström, Karl Johan, and Tore Hägglund. Advanced PID control. ISA-The Instrumentation, Systems and Automation Society, 2006, p. 26.